Manufacturing Services.

Our extensive experience and engineering background enables us to supply practical solutions to UK manufacturers.

We will work closely with you to ensure that we fully understand your requirements and, most importantly, provide a solution that can be successfully manufactured. Over the years, we have worked with a variety of clients including:

Our focus is delivering a great service to our clients. It doesn’t matter whether it’s producing a product design, prototype or production tooling, we believe in working closely with a client to make sure that the most practical and cost-effective solution is achieved and their expectations are met.

Our manufacturing services:

We offer a wide range of services from assisting customers reading problem CAD files to creating CAD models. Our services include:

Our Software

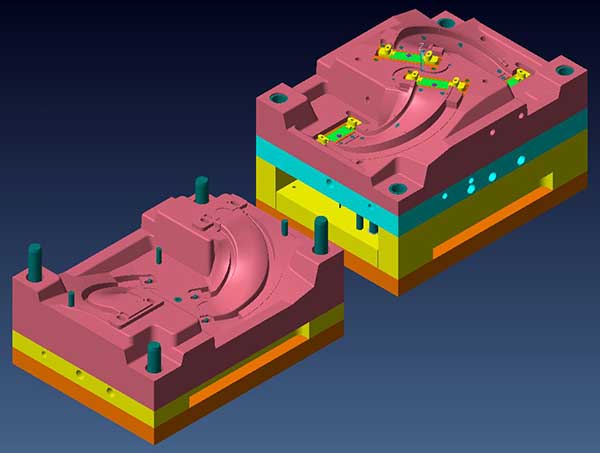

We use Vero’s Machining Strategist to create NC toolpaths ideal for both standard and High speed milling. This powerful CAM product generates optimum roughing and finishing toolpaths from the complex shapes generated by 3D Cad systems.

After checking, the toolpaths are processed for your milling machine tool control. All programs are supplied with detailed tool set-up sheets to ensure that the machine operator has all the information they need to run the programs with confidence.

Tel: 01296 613122 to discuss your requirements

With over 30 years’ experience in the industry and across multiple sectors, we can help you.